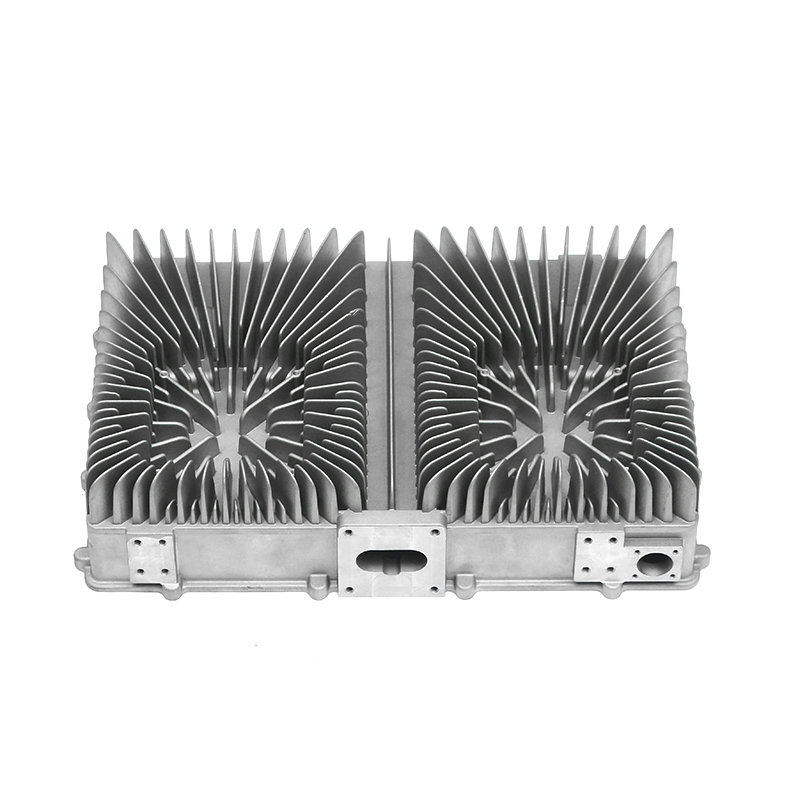

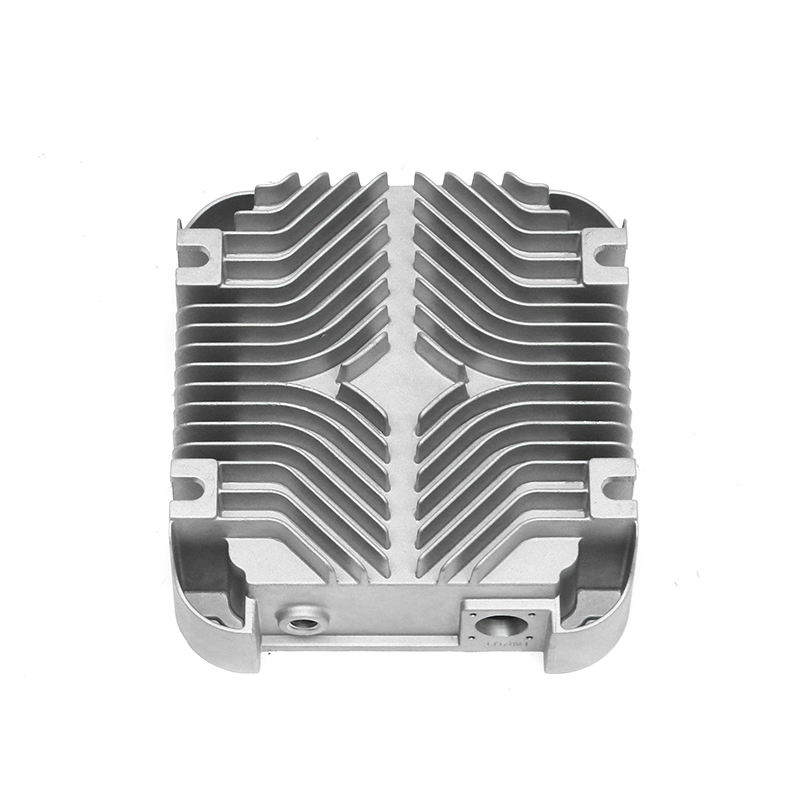

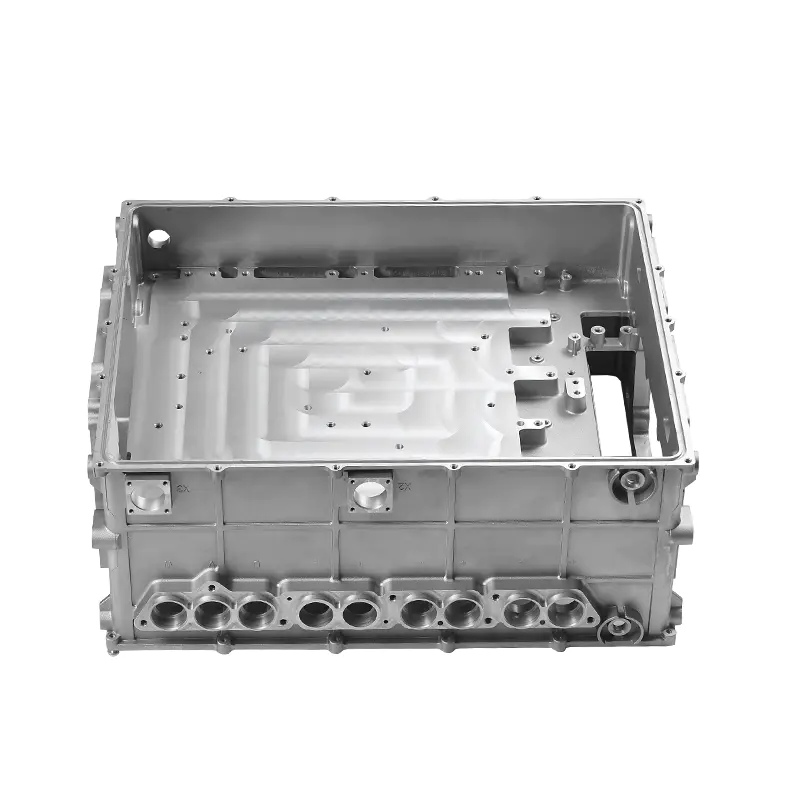

는 기어박스 하우징 전체 기어박스 시스템에서 중요한 지지 및 보호 역할을 하며, 그 디자인은 기어박스의 강성과 충격 저항에 직접적인 영향을 미칩니다. 합리적인 구조와 재료 선택은 외부 충격과 내부 하중을 받을 때 하우징이 안정적으로 유지되도록 보장하여 기어박스의 전반적인 성능과 서비스 수명을 향상시킵니다.

고강성 하우징은 작동 중 진동 및 부하 변화로 인한 기어박스의 변형을 줄여 동력 전달의 안정성을 향상시킬 수 있습니다. 기어박스가 작동 중일 때 내부 기어 맞물림은 큰 힘을 생성하므로 하우징의 충분한 지지가 필요합니다. 그렇지 않으면 기어박스 내부 부품이 잘못 정렬되거나 비정상적으로 마모될 수 있습니다. 따라서 하우징의 구조 설계는 다양한 방향에서 오는 힘을 고르게 견딜 수 있도록 지지점을 합리적으로 분배하고 국부적인 응력 집중을 방지하며 다양한 작업 조건에서 기어박스가 안정적으로 유지될 수 있도록 보장해야 합니다.

는 impact resistance of the housing is also crucial, especially in complex use environments, where the gearbox may be subjected to severe external impacts, such as bumps on the road, sudden changes in load or other external forces. If the housing is not impact-resistant enough, it may be deformed due to external impacts, and even affect the normal operation of internal parts. Therefore, in the design of the shell, materials with a certain toughness are usually used so that they can effectively absorb energy when impacted instead of directly transferring it to the internal structure. In addition, a reasonable structural layout, such as reinforcing ribs or multi-layer support structures, can further enhance the shell's impact resistance, so that it can still maintain normal operation in sudden situations.

는 choice of materials has an important impact on the rigidity and impact resistance of the shell. Usually, the shell is made of high-strength metal materials, so that it has good impact resistance while providing sufficient support. Different processing methods will also affect the final performance of the shell. For example, the casting process can improve the density of the material, thereby improving its strength and durability, while some special surface treatment technologies can enhance the shell's wear and corrosion resistance, so that it can maintain stable performance in different environments.

는 internal structure design of the shell also needs to take into account the needs of rigidity and impact resistance. Reasonable internal reinforcement structure can effectively disperse the load, so that the shell is not easy to deform when subjected to external force. At the same time, certain support points are usually designed inside the shell so that it can fit more closely with the internal parts, thereby reducing loosening caused by impact or vibration. In addition, some housings are thickened in certain areas to enhance local bearing capacity, thereby improving the stability of the overall structure.

는 design of the installation method and connection parts are also important factors affecting rigidity and impact resistance. A reasonable installation structure can ensure that the housing is tightly combined with other components to avoid affecting the normal operation of the gearbox due to looseness. At the same time, the fixing method of the housing needs to take into account the load changes in different environments to ensure that it will not be deformed or damaged due to stress accumulation during long-term use. In addition, some special connection methods, such as multi-point fixing or strengthening connectors, can also further enhance the stability and impact resistance of the housing.

추천상품

유명 기업에서 제공하는 제품은 사용자들의 깊은 신뢰를 받고 있습니다.