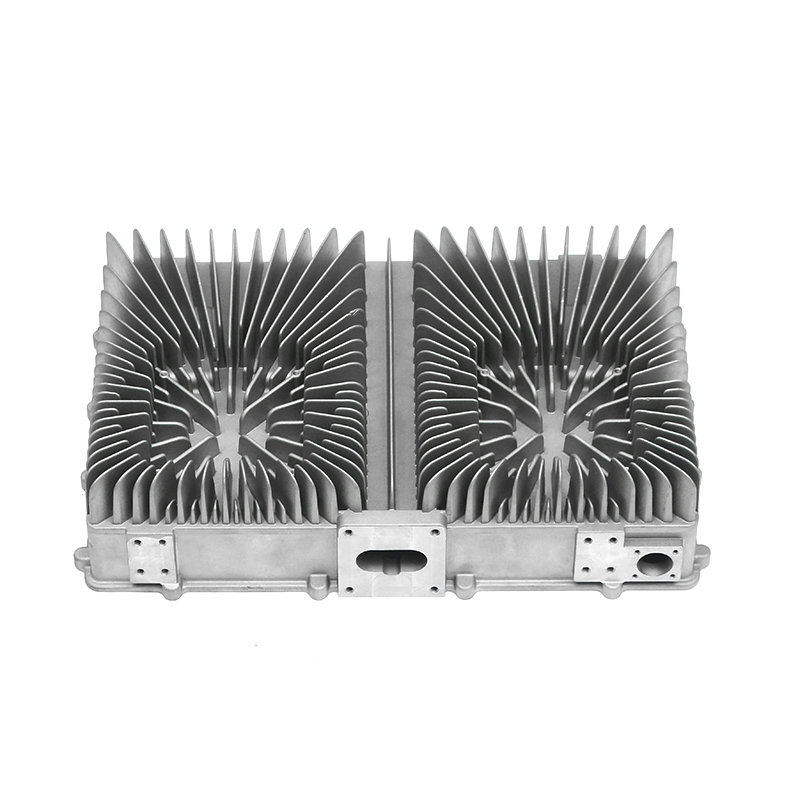

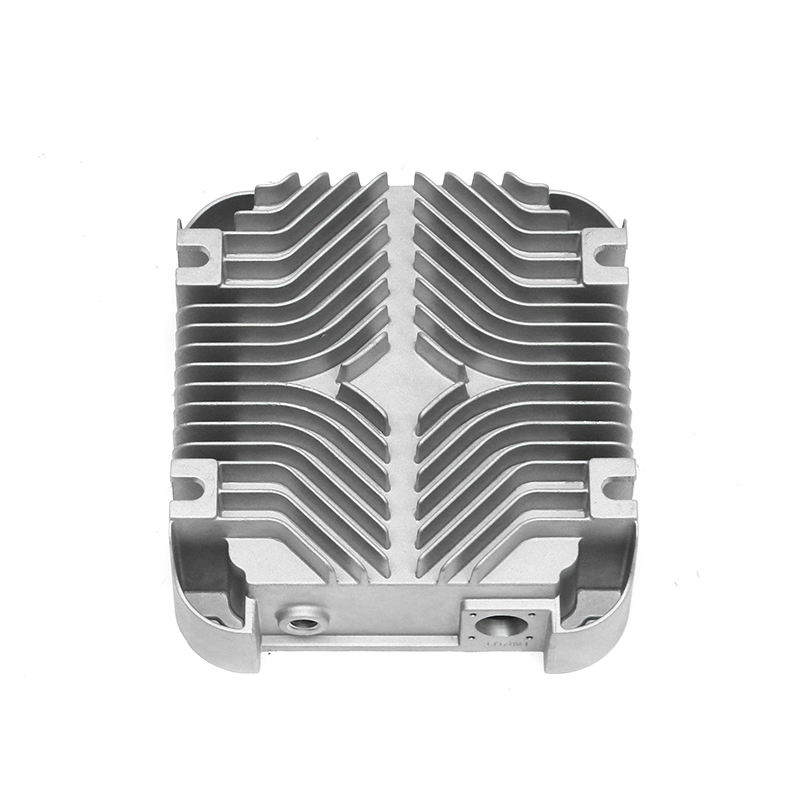

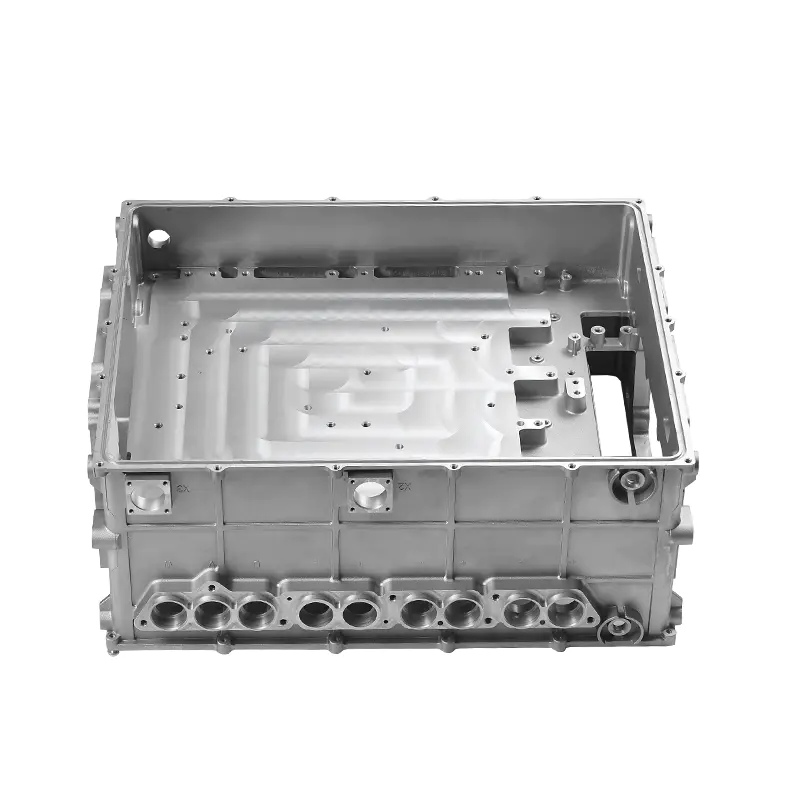

다이캐스팅 생산 과정에서 신에너지 모터 하우징 다이캐스팅 , 에너지 소비를 최적화하고 경제를 개선하는 것이 중요합니다. Reasonable process design, material selection, equipment management and optimization of production process can achieve the goal of energy saving and consumption reduction while ensuring product quality.

생산 과정에서는 원료의 활용률을 최적화하는 것이 필요합니다. Reasonable selection of suitable alloy materials can not only ensure that the housing has good thermal conductivity and mechanical strength, but also reduce redundant energy consumption. By accurately calculating material requirements, reducing waste, optimizing alloy composition, and reducing energy consumption in the smelting process, while improving material recovery rate, the overall production cost can be reduced.

제련 온도를 합리적으로 설정하고 온도 안정성을 확보하면 에너지 손실을 줄일 수 있습니다. 이 과정에서 자동화된 온도 제어 시스템과 결합된 효율적인 가열 장비를 사용하면 에너지 활용도를 향상시킬 수 있습니다. At the same time, optimizing the thermal insulation performance of the smelting furnace and reducing heat loss can also effectively reduce energy consumption. In addition, reasonable production planning and avoiding frequent startup and shutdown can reduce energy waste and improve the operating efficiency of equipment.

Efficient mold design can reduce material waste, improve the yield rate, reduce the defective rate, and reduce the extra energy consumption caused by rework. Reasonable optimization of the mold cooling system so that it can cool down quickly and remain stable can effectively shorten the production cycle and improve production efficiency. The use of advanced mold materials and surface treatment technology to improve the durability of the mold can reduce the frequency of mold replacement and reduce long-term production costs.

다이캐스팅 장비의 선택 및 사용에 있어서 에너지 절약형 다이캐스팅 기계를 사용하는 것이 효과적인 방법입니다. Modern intelligent die-casting equipment is usually equipped with an automatic adjustment system that can reasonably allocate energy consumption according to production needs and reduce unnecessary electricity use. At the same time, optimizing the hydraulic system, improving power transmission efficiency, and reducing energy loss can also further reduce overall energy consumption without affecting production efficiency.

Through automated equipment and intelligent management systems, the production rhythm can be optimized, waiting time can be reduced, and overall production efficiency can be improved. In addition, the production batches can be reasonably arranged to avoid the problem of excessive energy consumption caused by small batch production, so that each production can achieve higher energy utilization.

The scraps and waste generated during the production process can be processed through a reasonable recycling system and put back into use to reduce the consumption of raw materials, thereby reducing production costs. In addition, improving waste gas treatment technology, reducing energy waste, and making the entire production process more environmentally friendly can also bring long-term economic benefits to the company.

In daily management, strengthening the maintenance of equipment can ensure the long-term efficient operation of the equipment and avoid additional energy consumption caused by failures. At the same time, professional training for operators to improve their awareness of energy-saving production and enable them to take energy-saving measures in the production process is also an important part of optimizing overall energy consumption.

추천상품

유명 기업에서 제공하는 제품은 사용자들의 깊은 신뢰를 받고 있습니다.